Wire EDM & Micro Wire EDM

Today’s engineers are designing miniature components with extremely tight tolerances. For most shops, this pushes their limits. At Integrity Wire EDM, this is our daily work!

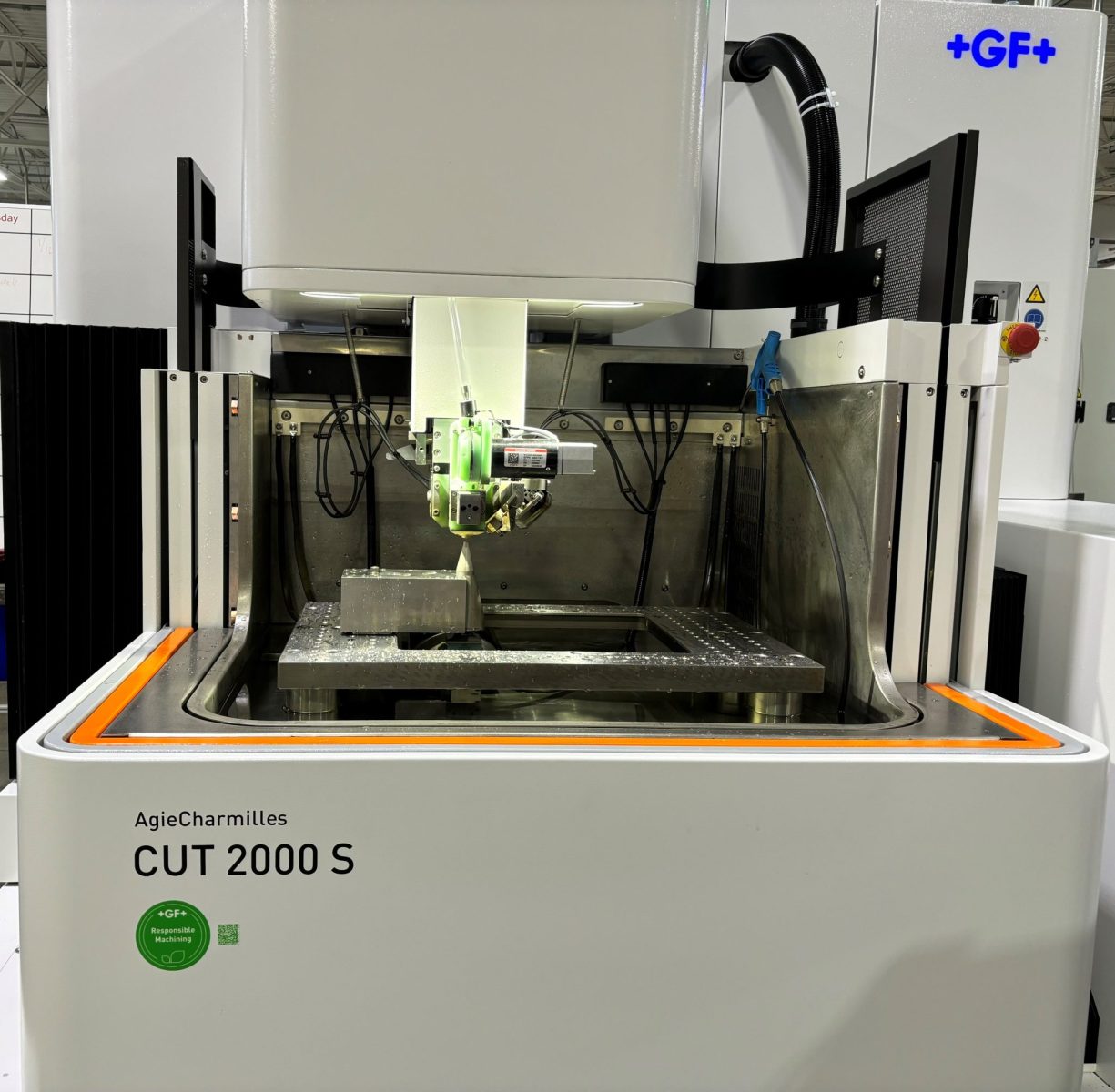

Integrity Wire EDM utilizes AGIE Wire EDM equipment to deliver the close tolerance capabilities for your most demanding projects.

We feature:

- Close tolerances down to +/- .00004” or +/- .001 microns

- Surface Finishes available to 4 rms (carbide or steel)

- True dimensional shapes and corners

- 2 and 4 axis work

- Cutting square to top and bottom

- High speed main and trim cuts

- Carbide specialty skills

- No core cutting

- Corner radius down to .0015”

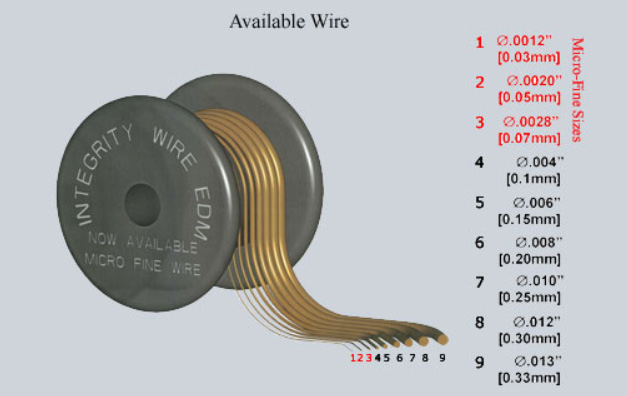

- .001-.013 Wire Ø capabilities

- Continuous Production

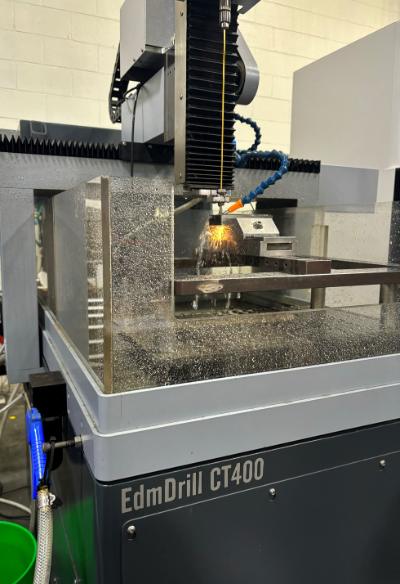

ED Bore (Hole Popping):

- The ability to put a hole through hard or soft material

- Hole sizes from 0.3mm to 3.0mm